Learn How to Build Stairs

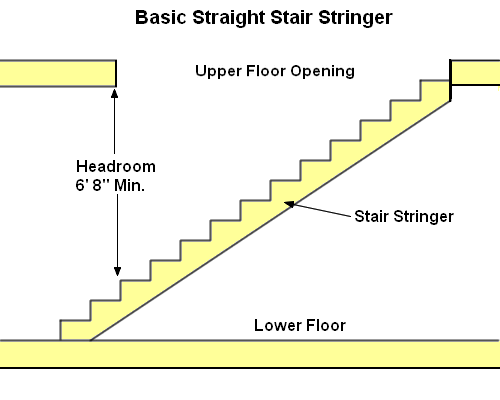

In order to advance your carpentry career you should learn how to build

stairs. If you can cut a roof then learning how to cut and install steps

should be fairly easy. The rise and run involved with step building are

similar to roof framing in many ways. Even basic straight run steps are

slightly different from one framing job to the next. There are strict guidelines that must be followed in order to construct a set of steps that will be sturdy, safe to navigate, and satisfy the building inspector. The following information is the method I use for site built steps.

Local Building Codes

Long gone are the days of building steps that are too steep, shoddily constructed, and with insufficient headroom. Most local building codes are very strict and have specific guidelines for building steps. In order to know how to build them you must be familiar with these local ordinances.

New Stair Building Forum

Most Common Building Codes

length of the stairway. This height is not only so people won’t bump

their heads easily but also for moving furniture.

height should be between 34 and 38 inches measured vertically from the

treads bull nose. A handrail should be provided on one side of every set

with 4 risers or more. Handrails must not protrude into stairway path

more than 4 1/2″

shall not be more than 7 3/4″ and not vary more than 3/8″ from greatest

to least. Be careful on this one, I’ve seen the riser height anywhere

from 7 7/16″ to 8 1/8″ and not allowed to vary more than 1/8″.

Formula for Site Built Steps

It doesn’t matter what type of staircase you are building, straight, L

shaped with a landing, curved, complete turn around 180 degree, or

winders. You must determine the overall rise and run, then divide it into comfortable increments.

In house framing this distance is usually from the first floor to the second or from the basement floor to the first floor.

Instructions on How to Build Steps

In this stair building tutorial we will be constructing a straight

set using three 2 X 12 stringers, 2 X carpeted treads, and a 2 X 4

spacer board to allow drywall and a 3/4 finish stringer board to be

inserted by the finish carpenter.

The overall rise is 8′ 10 3/4″ with a overall run of 11′ 2 7/8″.

I use a Construction Master calculator to figure my roofs and steps. A regular calculator can be used, but measurements should be taken in inches rather than feet and inches. Using a regular calculator has been discussed on the carpentry math page. There is also a free 30 day trial download on the roof framing page. Pick your poison, grab your regular calculator or the free download and lets see if you can learn how to build steps.

Determine Overall Rise and Run

The overall rise and run of the steps is determined by measuring the

space where the staircase is to fit. Keep in mind what type of floor

covering is to be used when determining rise between floors. If ceramic

tile or similar material is to be used it must be figured into the rise.

Measure horizontally where the steps are to land with the understanding

that you need a minimum of three feet of clear space before any

obstructions to the direction of travel.

Find Rise of Each Step

7 1/2″ is considered the perfect step, we divide 106.75 by 7.5 to find

out how many steps are needed. 106.75 divided by 7.5 = 14.233 since we

can’t have .233 of a step we need to drop it and divide the overall rise

by 14. 106.75 divided by 14 = 7.625 or 7 5/8″.

now know that this set of steps requires 14 equal increments of 7 5/8″

to climb from one floor to the next. Write this number down, it is one

of the keys to a step building success story.

Find Run of Each Step

134.875 by 13 = 10.375 or 10 3/8″ run per stair tread. The actual run

of the steps will be more due to the bottom step riser and the added

bull nose of the tread. Make sure you will still have the three feet of

required clear space at the bottom of the steps before laying out the

stringers.

Rise and Run Using Construction Master

|

The use of a Construction Master calculator is much faster and accurate than a regular calculator. To find the rise and run of each step we only need to enter 8′ 10″ 1/2 Risers 14, riser size 7 5/8″, treads 13, |

Mobile App

|

Laying Out the Stringers

the proper length. I know this is easier said than done, #1 stock is

available, however most builders won’t supply it due to the added cost.

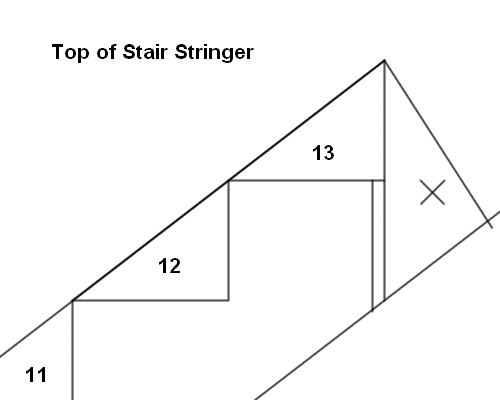

the framing square and beginning at the top of the stringer layout the

top plumb cut and the last tread. We now need to shorten the top cut by

the thickness of one riser, in our case 3/4″, so that the top tread will

be the same as all the rest. Failure to do this will require the top

tread to be 3/4″ wider than the rest resulting in possible rejection by

the building inspector, not a good story.

down the stringer and marking them as you go just like you would mark a

rafter using the step off method.

Write the number of treads in the triangular part that will be cut out

later until you have 13 treads marked out. These lay out marks are

critical to success and accuracy is the key.

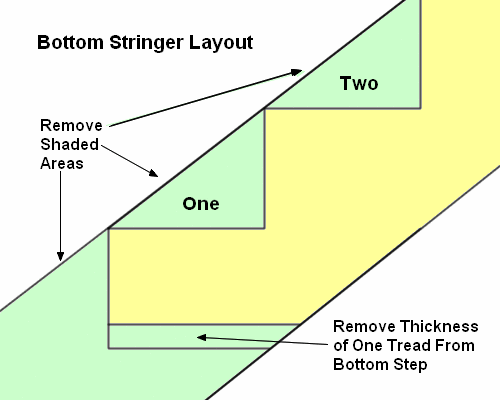

properly lay out the bottom of the stringer you must shorten the bottom

riser by the thickness of one tread, in our case 1 1/2″. This will

lower the entire stringer so when the bottom and top treads are attached

to the stringer they will be the same rise as all the rest.

you are satisfied that the stringer is properly marked out you can go

ahead and cut the top plumb and tread marks as well as the bottom level

and tread marks. We will test the stringer later and if it’s wrong you

can still get treads out of it and will not have wasted much material.

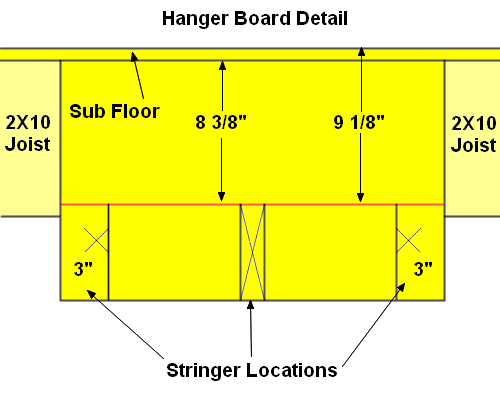

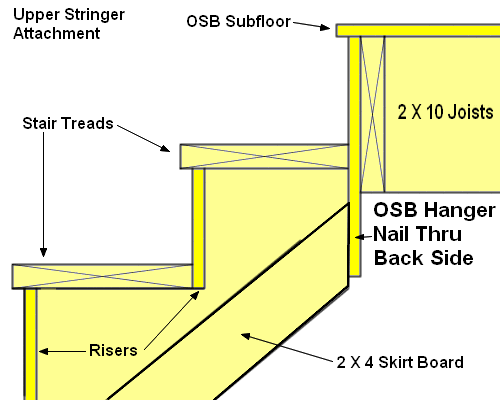

Attach Top of Stringers

floor joist to which it will rest against. With 2 X 10 floor joists, a

3/4″ subfloor, and 7 5/8″ riser height dropped an inch and a half this

means that the stringer will only bear against the joist 7/8 of an inch.

Not safe at all and a recipe for disaster, over the years I have found a

simple solution to this problem.

can now go ahead and lay out the hanger board to mark the location of

the stringers. Remember that the top of the stringer has been dropped

the thickness of a tread so hold it down accordingly. We can now go

ahead and mount the hanger board. Make sure to glue and nail it

securely.

Test the Stair Stringer

marked stringer which was cut on the top and bottom and hold it up to

the alignment marks on the hanger board.

to be certain you have the required three feet of clear space at the

bottom of the steps. Remember that when the bottom riser and tread are

installed the stairway will stick out another 1 3/4″ than the stringer

does now.

tread marks check to see if you have the required headroom. Remember

when the stair treads are installed they will be 1 1/2″ higher than the

marks.

Cutting the Stair Stringers

another decent 2 X 12, flush them up on the bottom, and temporarily nail

them together with 8 penny nails. One on each end should do it then

mark the cut top and bottom ends on the board below.

the skilsaw deeper than it needs to be and cut away, this will

eliminate the need to mark the next stringer because the saw has marked

it for you. With the stringers nailed together this reduces the chance

of the pattern slipping and causing errors.

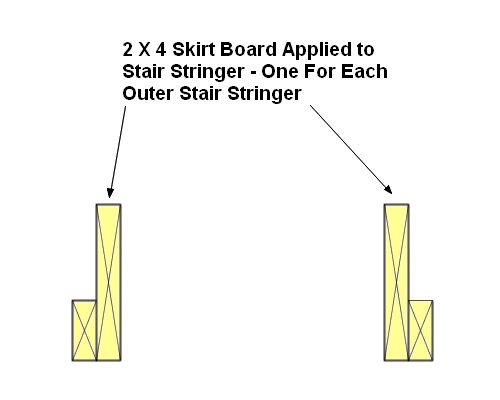

Apply Spacer Boards to Stringers

individual step a spacer board should be applied to the two outermost

stair stringers. If no finish stringer board is to be used then a 3/4″

board is enough to slide the drywall behind. Since we will be using a

finish stringer we will apply a 2 X 4.

Stair Building Instructions

Until this point not much work seems to have been done, but

without the proper planning and adherence to building codes we could

never get to the next step. It is now time to set the stair stringers in

place.

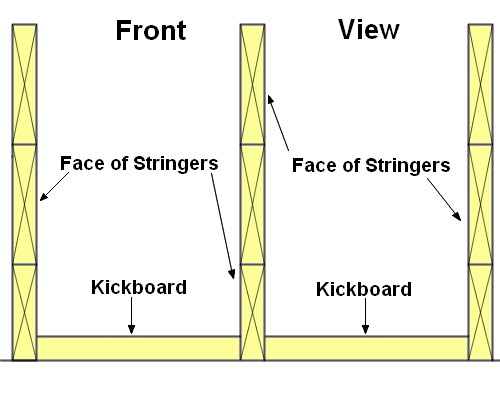

Set the two outside ones first,

glue and nail them securely thru the backside of the hanger board. Once

the two outside ones are in place set the center one.

a straight edge make sure the cut outs for riser and stair treads line

up. Slight variations of 1/8″ or less are normal and allowable.

you are satisfied the set of will meet code set, glue, and nail the

outside stringers into place. Place the middle one in the center of the

two outer stringers.

Attach Bottom of Stringers

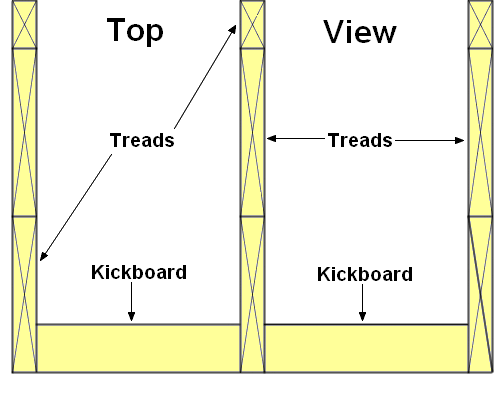

Some carpenters cut the bottom stringer around a 2 X 4 kick board but I

usually just glue and nail a 2 X 4 in between the stringers.

Cut the Risers

treads is to use scrap 3/4″ orientated strand board for risers. There is

always plenty of it laying around.

the risers at least 1/4″ less than the actual rise of the steps, in

this case we will go with 7 1/4″. Which just happens to be the width of a

1 X 8 if you would rather use those.

bottom riser is different than the rest because of the dropping of the

stringer. In this case it will need to be ripped to 6 1/8″. So we need

one at 6 1/8″ and twelve at 7 1/4″ for a total of thirteen.

Cut the Treads

Since the run is 10 3/8″, and we are required to have a bull nose of

3/4″ to 1 1/4″, our treads need to be between 11 1/8″ and 11 5/8″. Lucky

for us, a 2 X 12 just happens to be 11 1/4″, so we won’t need to rip

them. We need thirteen of them cut to the proper length.

Install Risers and Treads

Tips on How to Build Stairs

- Do not skimp on glue, a wasted tube of glue is better than a squeaky set of stairs. Glue everywhere wood touches wood.

- Always check local building codes, most municipalities have strict guidelines.

- Measure two or three times and cut once.

- Don’t

be intimidated by this, many carpenters are, I even know a few with 20+

years experience that have never learned how to build stairs.

- The easiest way to learn how to build steps is to start with something simpler like a set of three or four step stairs. The basic principle of building is the same only on a smaller scale.

Links to Related Carpentry Pro Framer Pages

|

|

|